Email nationalbuildingarts@gmail.com or call 206-351-7831.

Thanks!

Email nationalbuildingarts@gmail.com or call 206-351-7831.

Thanks!

Intern Positions Available at the National Building Arts Center

The St. Louis-based National Building Arts Center (NBAC; nationalbuildingarts.org) seeks applications for internships in cataloging, conserving and sorting its material and library collections. The internship can begin any time.

The NBAC promotes public awareness of the crucial roles of architecture, manufacturing, construction, and urban design in our built environment.

Located in Sauget, IL, the NBAC is a unique, emergent study center housing the nation’s largest and most diversified collection of building artifacts, supported with a research library offering broad holdings in architecture and allied arts. Our collection represents the single largest effort toward understanding the American built environment and the historical process of its creation.

Description of Internship

Projects

Interns will perform needed tasks on the following projects:

Contact

Larry Giles

lg@buildingmuseum.org

618-332-5000

NBAC

2300 Falling Springs

Sauget IL 62206

When the Missouri History Museum was creating its new exhibit A Walk in 1875 St. Louis, not surprisingly it turned to the National Building Arts Center to enhance the display with building artifacts. The exhibit presents a look at St. Louis in the year that Compton & Dry published their famous bird’s-eye perspective, Pictorial St. Louis. Curator Andrew Wanko worked with the Center to include remnants of a flounder-style house once located in LaSalle Park known as “Hlas House.” The house likely dated to the 1850s.

The flounder-style house once standing at 1611 South 11th Street became the home of the Bohemian Publishing Society — the first Czech Catholic national publishing house in America — from 1908-1954. At this address, the Society published Hlas (“Voice”), an influential Czech-language newspaper. When the house was wrecked, Center founder Larry Giles recovered the entrance and a window complete with enframement, sash and shutters. These fully-restored items greet visitors to A Walk in 1875 St. Louis, setting the historic scene.

The installation can be seen as part of the exhibit through February 16, 2016.

He’s a former infantry squad leader in the Marine Corps whose company was the inspiration for the film “Full Metal Jacket.”

After seeing combat in Vietnam and leaving the military, Larry Giles went on to develop a passion for preservation, amassing the largest collection of building artifacts in the country over the past 40 years.

Having been a Marine “really helps with organizational skills and the ability to tackle large projects and stay with them,” said Giles, 66, who in 2007 created the National Building Arts Center, located on a 15-acre site in Sauget, Illinois.There, 13 buildings of the former Sterling Steel Casting Co. foundry house crate after crate of history in the form of sculptures, columns, friezes, ornamental brick, ironwork and terra cotta.

Giles has long hoped to display the collection, establish a research library and have a degree program in conservation through a local university, but funding has been an obstacle. Items range from an assortment of more than 2,000 door knobs representing various architectural periods to a complete facade from St. Louis’ Gaslight Square. There’s also a collection of more than 100 complete cast iron storefronts, an ecclesiastical collection with artifacts from local Catholic churches and a glass collection featuring the vaulted glass atrium dome from the 1902 National Bank of Commerce in St. Louis.

Giles estimates he has approximately 300,000 items on the site, which at first glance looks like a ghost town after having been the workplace of almost 300 foundry workers. While most of the collection is from St. Louis buildings, other cities represented include Chicago, Philadelphia, Los Angeles and New York.

There are also thousands of items intended for the research library, such as books, photographs, drawings, prints and other materials, including the world’s largest collection of architectural postcards, which date mostly to the late 1800s.

A longtime history lover, Giles owned St. Louis Architectural Art Co., an architectural recovery, materials conservation and building restoration firm, for nearly 30 years before establishing in 2002 the St. Louis Building Arts Foundation, which controls the center.

“Larry has this encyclopedic knowledge,” said Steve Trampe, founder of real estate firm Owen Development and chairman of the foundation. “He’s not trained and he doesn’t have a doctorate but he’s got it all in his head. You can talk about the history of structural steel or the history of French architecture in St. Louis. He lives and breathes this and knows it like no one else.”

The center’s holdings are so comprehensive that the Brooklyn Museum in New York chose to transfer most of its collection of architectural artifacts there over the past several years. It features several thousand pieces, including terra cotta, carved stone, cast iron, cast cement, woodwork and signage, Giles said.

What attracted you to architectural history and conservation? I’ve been fascinated by the city’s history and architecture since childhood. My grandmother’s boyfriend, whom I referred to as grandpa as a kid, was a real St. Louis history buff. There were very few details about the city that he wasn’t privy to. He got me interested in history and the history of St. Louis. We used to ride around the city and he’d tell stories and point out places and buildings.

Why did you start the St. Louis Architectural Art Co.? It evolved out of a rehab company I started in 1972 called Soulard Resources. I started it with a couple of architecture students from Wash U. At that time there were close to 300 empty buildings in Soulard, and we wanted to stabilize the buildings that were vacant and vandalized, find people to take them over and build a community again. Soulard at that time looked like Dresden after the bombing. We had a romantic vision about what the neighborhood could be. We even went on radio trying to promote the area. After a year or two we realized we didn’t have the financial horsepower to get the company off the ground. When we closed Soulard Resources I continued the salvaging of historic materials and started the St. Louis Architectural Art Co.

Where did you get the idea for a museum for building artifacts? The idea for an architectural study collection goes back to the late 1930s. It was first proposed for the Jefferson National Expansion Memorial by Charles Peterson of the National Park Service, who is largely considered the father of preservation in the United States. He had support from the St. Louis preservation community at the time to salvage significant parts of the buildings that were being demolished for the arch grounds. They saved and put in warehouses artifacts similar to what we’ve got here to become part of the Museum of American Architecture. That project was abandoned in the early 1950s by the Park Service and the collections were disbursed.

What are the most significant pieces in your collection? Probably the cornice from the Title Guaranty building, originally the Lincoln Trust building, on the southwest corner of Seventh and Chestnut. It’s one of the finest terra cotta cornices anywhere in the world. It’s a series of sculptured winged victory figures that surrounded the building at the top. It was designed by St. Louis’ most prestigious architectural firm, Eames and Young. It was built right across the street from the Wainwright Building.

What’s in your ecclesiastical collection? Altars, baptismal fonts, communion railings and statues. Most of the items are from former Catholic churches that were sold off by the Archdiocese when parishes were consolidated on the north side of St. Louis. We worked with the Archdiocese and agreed to dismantle and preserve a lot of the marble work from a half dozen really significant churches that were going to be sold off. There are probably about 100 crates of materials, and the crates are about 30 cubic feet each.

Where can people view some of the artifacts? At the Missouri Botanical Garden’s Temperate House behind the Climatron there’s a carved stone entrance from a former Catholic school. It’s permanently installed. The Sheldon Art Galleries have an installation. The Missouri History Museum has an exhibit called “Seeking St. Louis” with some artifacts from St. Louis buildings. There’s a cast iron storefront and examples of roofing tiles. There’s an entrance from one of the first schools built in St. Louis. We also have a great exhibit atWells Fargo, built for A.G. Edwards.

Where to you get most of your funding? Right now from the sale of duplicate or unwanted or nonessential material in the collection. There’s a lot of duplication in the collection, like some of the sculptures and medallions. We’re putting a catalog together to offer some of this material for sale.

What do you enjoy most about what you do? I enjoy the physical, hands-on aspect of salvage work. I love operating cranes, fork lifts, boom trucks, air compressors, air chisels and pneumatic hammers, and using scaffolding and rigging. I’m also learning new things all the time, which is stimulating.

What was your first job? I worked as a carpenter during summer vacations when I was 12 and 13. I worked with a company that was building new homes out in South County. I also sold newspapers. I sold the Post and the Globe from a paper stand at Big Bend and Manchester when I was probably about 12.

Where you might find Larry Giles

That terrra cotta roofing tile is now acknowledged to be the best product for protection of buildings from storm and rain has been proven by its increased and continued acceptance, and as evidenced by reviewing many of the modern structures such as residences, schools, libraries, universities, churches, railway depots, freight buildings, factories, stables, etc., where we find that the above material has been generously used with satisfactory results.

Looking forward to the expectant demand for this product in the future, The Mound City Roofing Co. was organized for the manufacture of terra cotta roofing tile with all the accessory trimmings of the most modern shapes, highest grade and superior quality in various colors and glazes. The above assurance is here given on the satisfactory tests made of their clay which is especially and essentially adapted for the manufacture of terra cotta roofing tile.

Looking forward to the expectant demand for this product in the future, The Mound City Roofing Co. was organized for the manufacture of terra cotta roofing tile with all the accessory trimmings of the most modern shapes, highest grade and superior quality in various colors and glazes. The above assurance is here given on the satisfactory tests made of their clay which is especially and essentially adapted for the manufacture of terra cotta roofing tile.

Being centrally located in the heart of St. Louis, and having superior shipping facilities, we can easily reach any territory in the United States.

Our clay is of the finest grade of Shale and makes roofing tile of superior quality and color, burning a solid red throughout and burnt to a very high temperature which insures it against disintegration form the most sever climatic influences. It is also very compact and dense. In manufacturing our tile we employ none but skilled mechanics or experts that money can secure. This in connection with the most modern machinery and up to date plant in United States, enables us to produce a tile which is second to none manufactured in this country.

Roofing tile, without doubt is one of the best known non-conductors of both heat and cold when well burnt but not vitrified. An absolutely vitrified tile in a great many aspects has the same objectionable features as slate, namely: being brittle, a conductor of both heat and cold, will not absorb condensation which in certain climates and seasons of the year causes a constant drip, making a very unsatisfactory roof when used on open construction. Also when it is subjected to a high temperature from an adjoining fire, it will crack and fly all to pieces the same as slate. Well burnt shale roofing tiles will not break from excessive heat or from walking over them and when hung on strips and wired on roofs, will not break from the settling or structural motion of the roof as slate very often does.

Nothing can be more desirable than roofing tiles for a fore proof building; especially does this refer to buildings that are more or less exposed to the danger of fire caused from flying sparks from engines or from adjoining buildings on fire.

The initial cost of tile in some localities exceeds that of slate, but the ultimate economy is accepted by all who are familiar with its use. The hard burnt shale tile well laid on the roof will last indefinitely, while no other roofing material has this record. A well burnt shale tile in manufacturing is subjected to a temperature of about 2000 degrees Fahrenheit and will stand 200 % more heat than slate without injury to the tile.

Method of Laying Tile

It is an erroneous idea that interlocking roofing tiles are very difficult and expensive to lay: in fact it is just the opposite, for on account of being made to easily fit into each other, they are quickly and easily put in place. The interlocking feature dispenses with the use of elastic cement which must be used with plain Spanish tile.

There are two kinds of roof construction: one called closed construction and the other open construction.

In closed construction the roof is prepared just the same as the slate, being first sheathed, then covered with one layer of heavy roofing felt: held in place by common plaster laths laid vertically at twenty four inches center. On these are nailed one inch by two inch wooden strips laid horizontally and spaced according to length of the different kind of tile to be used. On these the tile are hung and wired to the roof.

In open construction the same method is used—1×2 wood strips are mailed directly to rafters or secured to steel trusses. Tile laid on open construction can be made water tight by laying spun oakum in joints to form a cushion or filling the joints on under side with cement mortar.

Vitreous Face Tile

Our vitreous face tile surpasses anything of its kind on the market. This class of tile, which is somewhat more expensive, is preferred by a great many architects for several reasons namely: being vitrified on the exposed surface will not absorb any moisture from outside: the opposite or under side being slightly absorbent prevents the possibility of dripping caused through condensation at certain seasons of the year: it will always remain clean and has one solid red color throughout the entire body of tile.

Colors and Glazes

Although the natural burnt color of our tile is a deep bright red, which is standard color and will be shipped on orders unless otherwise specified: we manufacture all the tile and trimmings in the catalogue in a full glazed finish in shades blending from dark to light of green, yellow, blue, brown, white and mottle: also a dull green finish which is produced direct by firing and not by artificial means after burning etc., such as sand blasting.

Glass Tile

We furnish glass tiles in shapes “A”, “C” and “S”, for introducing light through the roof. They can be placed where required and readily moved at any time, if so desired, as they are fac-similes of terra cotta tile in every particular, in shape and form.

Valley and Hip Tile

We furnish cut hip and valley tile, as well as cut and filled valley tile, at an additional charge. Roof plans and elevations, with measurements, must be furnished to do this work accurately.

Graduated Tile

Are made to order, to fit all kinds of towers.

Promenade Tile

For flat roofs of office buildings, apartment houses, etc.: are far in advance of gravel or composite roofs, as they shed the water much better. These tile, laid in asphalt, will make the best, cleanest and most substantial flat roofs, and are absolutely fire and water proof.

Shingle Tile

Better, handsomer and more durable than slate.

Trimmings

Trimmings made for hips, ridges and terminations of same, and if desired, from any design furnished by the architect.

Slate Roof Trimmings

As there is constantly a demand for terra cotta trimmings for slate roofs, we have devoted special attention to suitable and appropriate designs for this class of work.

Tile on Wood Strips

Cover sheathing with one layer of asphalt roofing paper weighing 30 lbs. to square. Fasten it down with plaster lath laid perpendicularly 24 inches on centers. Wood strip to be 1 in. x 2. in, surfaced one side and nailed horizontally over lath, spaced accurately, according to pattern of tile used. Top strip to finish 2 ½ inches from apex of roof, and can’t strip to be doubled. First strip must be set to allow eave course to project 2 inches into gutter to allow free drip.

All valleys to have 1 in x 2 in strips nailed at each side, over which to turn the valley metal.

All crestings and hip rolls to be laid in cement, colored to match shade of tile and all the joints are to be neatly pointed with same cement. A hip board of necessary thickness and width, according to size of hip roll, is to be well fitted and nailed to top of hip rafter for receiving and nailing hip roll to same.

Wiring

Each tile is gable and eave course and every third tile in body of roof must be securely fastened with No. 18 copper wore by attaching to lug on underside of tile, then passing wire through a galvanized staple driven into sheathing directly under lug and winding around nail at one side of tile.

Valley Metal

The valleys are to be covered with metal which is to be well fitted over the valley strips and to extend beyond the outside of the same, not less than three inches on each roof. Separate pieces of roofing-felt are to be laid under the valley metal wide enough to extend well under the main roofing-felt on each side of the valley.

The roofing-felt is to extend over the top of the outer three inches of valley metal up to the valley strip on each side of valley gutter.

Where roofing tile comes against brick wall, it is to be fitted as closely as practicable and then lay lead or copper flashing well bent and fitted to the tile and also against wall not less than six inches high, then cover this flashing with cap flashing well and securely fitted into joints of brick work. (See illustration Cut 4)

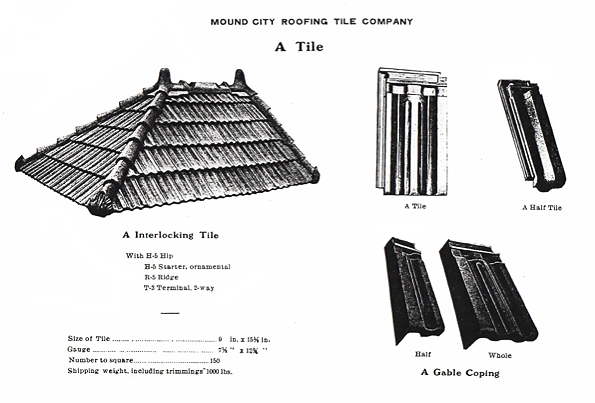

Mound City Roofing Tile Company “A Tile” is shown in this illustration. “A Tile” along with “A Half Tile” are shown in the upper right. Half and Whole Gable Copings are shown in the lower right. The Left side of the illustration shows how they are Interlocking Tile and also shows specifications such as size, gauge, number to square, and shipping weight including trimmings.

This illustration shows Mound City Roofing “B Tile” or B Interlocking Tile. In the upper left side of the illustration a section of roof shows B Interlocking Tile, below that illustration B Gable Coping, B Tile, and B Half Tile are shown. The right side of the illustration shows the specifications of B Tile such as the Size, Gauge, Number to Square, and Shipping weight, including trimmings.

This illustration shows Mound City Roofing Panama Tile. The upper right side of the illustration shows Panama Gable Coping Whole and Half. Below in the lower right is shown the Panama Tile, Closed Eave, and Half Tile. The left side of the illustration shows a section of Panama Tile and the specifications such as the Size of the Tile, Gauge, Number to Square, and Shipping weight, including trimmings.

This illustration shows Mound City Roofing S Spanish Tile. The right side of the illustration shows S Spanish Tile Flat Tops, Closed Eaves, Left Gable Coping, S Spanish Tile, and Right Gable Coping. The left side of the illustration shows a section of S Spanish Tile and the specifications of the tile, such as Size of Tile, Gauge, Number to Square, and Shipping Weight, including trimmings.

This illustration shows Mound City Roofing C Spanish Tile. The right side of the illustration shows C Spanish Tile, Right Gable Coping, Left Gable Coping, Closed Eave, and Flat Top. The left side of the illustration shows a section of C Spanish Tile and the specifications of the tile, such as Size of Tile, Gauge, Number to Square, and Shipping Weight, including trimmings.

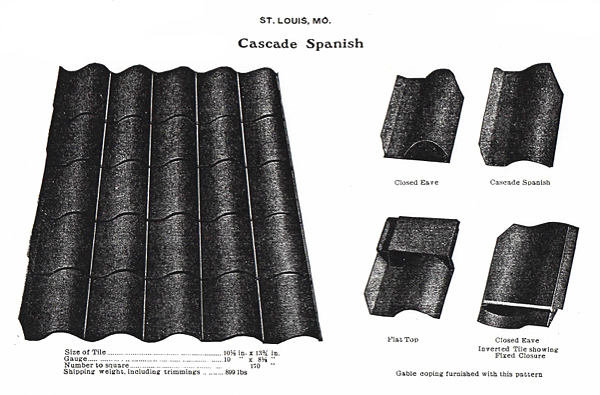

This illustration shows Mound City Roofing Cascade Spanish Tile. The right side of the illustration shows Cascade Spanish Tile, Closed Eave, Flat Top, and Closed Eave (Inverted tile showing fixed closure). The left side of the illustration shows a section of Cascade Spanish Tile and the specifications of the tile, such as Size of Tile, Gauge, Number to Square, and Shipping Weight, including trimmings.

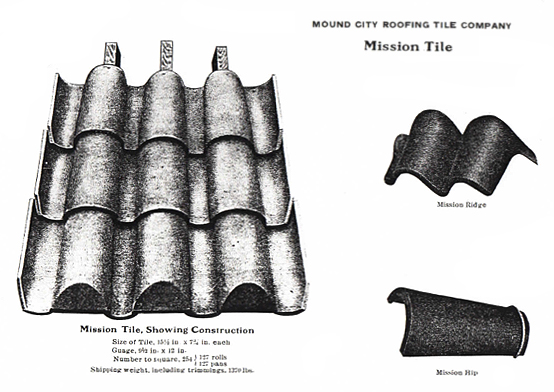

This illustration shows Mound City Roofing Mission Tile. The right side of the illustration shows Mission Ridge Tile and Mission Hip Tile. The left side of the illustration shows a section of Mission Tile and the specifications of the tile, such as Size of Tile, Gauge, Number to Square, and Shipping Weight, including trimmings.

This illustration shows Mound City Roofing Greek Tile. The right side of the illustration shows Octagon Cover Tile, Pan Tile, Hexagon Cover Tile, and Greek Ridge Tile. The left side of the illustration shows a section of Greek Tile and the specifications of the tile, such as Size of Tile, Gauge, Number to Square, and Shipping Weight, including trimmings.

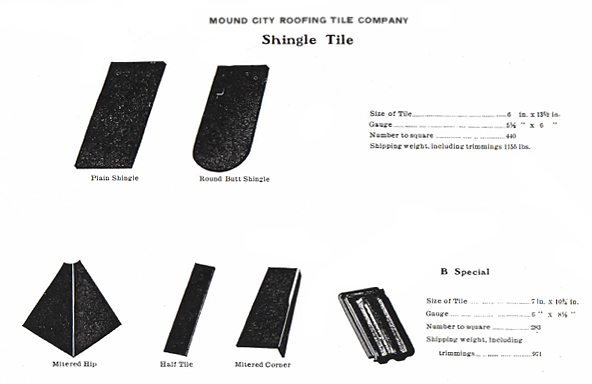

This illustration shows Mound City Roofing Shingle Tile. The left side of the illustration shows Plain Shingle, Round Butt Shingle, Mitered Hip, Half Tile, Mitered Corner, and B Special. The right side of the illustration shows the specifications of the Shingle Tile and the B Special tile, such as Size of Tile, Gauge, Number to Square, and Shipping Weight, including trimmings.

6in. x 9in. x 3/4in. thick; weight per square 938 lbs.

Number to square. 268

6in. x 9in. x 1in. thick; weight per square, 1100 lbs.

Promenade Tile

The “Promenade” tile is made especially for covering flat roofs and promenades.

It is 6 in by 9 in by ¾ or 1 in., in size, laid in asphaltum with smooth face on top, which enables the water to easily run off with 1% fall.

This tile also makes a most excellent paving material. It is impervious to moisture, being a very compact body and burnt to a high degree of heat.

Specifications for laying Promenade Tile

First lay one dry sheet of building paper, every sheet lapping preceding one 2 inches. On this lay 4 ply No.2 14 lb. tarred felt. Mop between each sheet with hot tremolite.

Over this entire surface of felt laid, spread a uniform coat of hot tremolite, which is to be throughly set before laying of tile.

On this surface lay 6x9x1 inch thick hard burned red tile, all joints to be straight and left open not less than 3/8 of an inch.

Al tile is to be left clean and free from defects.

All eaves and outlets to have a copper duplex eave stop. All walls and skylight to be flashed and cap flashed with 14 oz. soft copper as follows:

*Base flashing 5 inches on roof or wall

*Cap flashing not less than 5 inches to extend 1 inch into brick joints, fastened with lead plugs and pointed with cement.

This illustration shows three hip tiles and the lengths, widths, heights, and weights for each of them.

Along with illustrations of three Plain Starters and below them three Ornamental Starters.

This illustration shows three hip tiles and the lengths, widths, heights, and weights for each of them.

Along with illustrations of three Plain Starters and below them three Ornamental Starters.

This illustration shows two hip tiles and the lengths, widths, heights, and weights for each of them.

Along with illustrations of two Plain Starters, two Ornamental Starters, and one Plain Hip Starter.

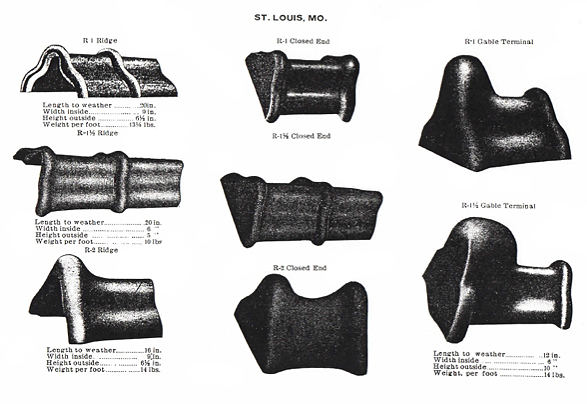

This illustration shows three ridge tile and there lengths, widths, heights, and weights. Along with illustrations of three Closed End tile and two Gable Terminals.

This illustration shows three Ridge Tiles and the lengths, widths, heights, and weights for each of them. Along with illustrations of one Ventilator tile, one Closed End Tile and three Gable Terminals.

This illustration shows three Mound City Roofing Tile and the lengths, widths, heights, and weights for each of them. Along with an illustration of one large Finial, with a Ridge Tile and a Ridge Closed End tile below it.

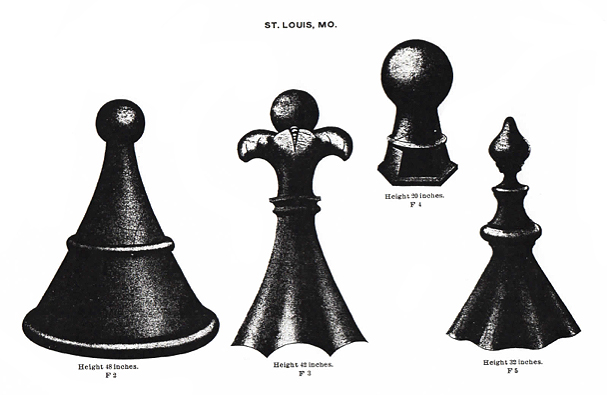

This is an illustration of four varying finials from Mound City Roofing Tile Company. From left to right, the first has a height of 48 inches, the second has a height of 42 inches, the third has a height of 20 inches and the fourth has a height of 32 inches.

Mound City Roofing Tile Company

Mound City Roofing Tile Company

That terrra cotta roofing tile is now acknowledged to be the best product for protection of buildings from storm and rain has been proven by its increased and continued acceptance, and as evidenced by reviewing many of the modern structures such as residences, schools, libraries, universities, churches, railway depots, freight buildings, factories, stables, etc., where we find that the above material has been generously used with satisfactory results.

Looking forward to the expectant demand for this product in the future, The Mound City Roofing Co. was organized for the manufacture of terra cotta roofing tile with all the accessory trimmings of the most modern shapes, highest grade and superior quality in various colors and glazes. The above assurance is here given on the satisfactory tests made of their clay which is especially and essentially adapted for the manufacture of terra cotta roofing tile.

Being centrally located in the heart of St. Louis, and having superior shipping facilities, we can easily reach any territory in the United States.

Our clay is of the finest grade of Shale and makes roofing tile of superior quality and color, burning a solid red throughout and burnt to a very high temperature which insures it against disintegration form the most sever climatic influences. It is also very compact and dense. In manufacturing our tile we employ none but skilled mechanics or experts that money can secure. This in connection with the most modern machinery and up to date plant in United States, enables us to produce a tile which is second to none manufactured in this country.

Roofing tile, without doubt is one of the best known non-conductors of both heat and cold when well burnt but not vitrified. An absolutely vitrified tile in a great many aspects has the same objectionable features as slate, namely: being brittle, a conductor of both heat and cold, will not absorb condensation which in certain climates and seasons of the year causes a constant drip, making a very unsatisfactory roof when used on open construction. Also when it is subjected to a high temperature from an adjoining fire, it will crack and fly all to pieces the same as slate. Well burnt shale roofing tiles will not break from excessive heat or from walking over them and when hung on strips and wired on roofs, will not break from the settling or structural motion of the roof as slate very often does.

Nothing can be more desirable than roofing tiles for a fore proof building; especially does this refer to buildings that are more or less exposed to the danger of fire caused from flying sparks from engines or from adjoining buildings on fire.

The initial cost of tile in some localities exceeds that of slate, but the ultimate economy is accepted by all who are familiar with its use. The hard burnt shale tile well laid on the roof will last indefinitely, while no other roofing material has this record. A well burnt shale tile in manufacturing is subjected to a temperature of about 2000 degrees Fahrenheit and will stand 200 % more heat than slate without injury to the tile.

Method of Laying Tile

It is an erroneous idea that interlocking roofing tiles are very difficult and expensive to lay: in fact it is just the opposite, for on account of being made to easily fit into each other, they are quickly and easily put in place. The interlocking feature dispenses with the use of elastic cement which must be used with plain Spanish tile.

There are two kinds of roof construction: one called closed construction and the other open construction.

In closed construction the roof is prepared just the same as the slate, being first sheathed, then covered with one layer of heavy roofing felt: held in place by common plaster laths laid vertically at twenty four inches center. On these are nailed one inch by two inch wooden strips laid horizontally and spaced according to length of the different kind of tile to be used. On these the tile are hung and wired to the roof.

In open construction the same method is used—1×2 wood strips are mailed directly to rafters or secured to steel trusses. Tile laid on open construction can be made water tight by laying spun oakum in joints to form a cushion or filling the joints on under side with cement mortar.

Vitreous Face Tile

Our vitreous face tile surpasses anything of its kind on the market. This class of tile, which is somewhat more expensive, is preferred by a great many architects for several reasons namely: being vitrified on the exposed surface will not absorb any moisture from outside: the opposite or under side being slightly absorbent prevents the possibility of dripping caused through condensation at certain seasons of the year: it will always remain clean and has one solid red color throughout the entire body of tile.

Colors and Glazes

Although the natural burnt color of our tile is a deep bright red, which is standard color and will be shipped on orders unless otherwise specified: we manufacture all the tile and trimmings in the catalogue in a full glazed finish in shades blending from dark to light of green, yellow, blue, brown, white and mottle: also a dull green finish which is produced direct by firing and not by artificial means after burning etc., such as sand blasting.

Glass Tile

We furnish glass tiles in shapes “A”, “C” and “S”, for introducing light through the roof. They can be placed where required and readily moved at any time, if so desired, as they are fac-similes of terra cotta tile in every particular, in shape and form.

Valley and Hip Tile

We furnish cut hip and valley tile, as well as cut and filled valley tile, at an additional charge. Roof plans and elevations, with measurements, must be furnished to do this work accurately.

Graduated Tile

Are made to order, to fit all kinds of towers.

Promenade Tile

For flat roofs of office buildings, apartment houses, etc.: are far in advance of gravel or composite roofs, as they shed the water much better. These tile, laid in asphalt, will make the best, cleanest and most substantial flat roofs, and are absolutely fire and water proof.

Shingle Tile

Better, handsomer and more durable than slate.

Trimmings

Trimmings made for hips, ridges and terminations of same, and if desired, from any design furnished by the architect.

Slate Roof Trimmings

As there is constantly a demand for terra cotta trimmings for slate roofs, we have devoted special attention to suitable and appropriate designs for this class of work.

Tile on Wood Strips

Cover sheathing with one layer of asphalt roofing paper weighing 30 lbs. to square. Fasten it down with plaster lath laid perpendicularly 24 inches on centers. Wood strip to be 1 in. x 2. in, surfaced one side and nailed horizontally over lath, spaced accurately, according to pattern of tile used. Top strip to finish 2 ½ inches from apex of roof, and can’t strip to be doubled. First strip must be set to allow eave course to project 2 inches into gutter to allow free drip.

All valleys to have 1 in x 2 in strips nailed at each side, over which to turn the valley metal.

All crestings and hip rolls to be laid in cement, colored to match shade of tile and all the joints are to be neatly pointed with same cement. A hip board of necessary thickness and width, according to size of hip roll, is to be well fitted and nailed to top of hip rafter for receiving and nailing hip roll to same.

Wiring

Each tile is gable and eave course and every third tile in body of roof must be securely fastened with No. 18 copper wore by attaching to lug on underside of tile, then passing wire through a galvanized staple driven into sheathing directly under lug and winding around nail at one side of tile.

Omit plaster lath and fasten felt with small nails and tin cap or large headed felt nails. Nail tile directly to sheathing with one or two galvanized or copper nails, as pattern selected may demand.

Valley Metal

The valleys are to be covered with metal which is to be well fitted over the valley strips and to extend beyond the outside of the same, not less than three inches on each roof. Separate pieces of roofing-felt are to be laid under the valley metal wide enough to extend well under the main roofing-felt on each side of the valley.

The roofing-felt is to extend over the top of the outer three inches of valley metal up to the valley strip on each side of valley gutter.

Where roofing tile comes against brick wall, it is to be fitted as closely as practicable and then lay lead or copper flashing well bent and fitted to the tile and also against wall not less than six inches high, then cover this flashing with cap flashing well and securely fitted into joints of brick work. (See illustration Cut 4)

By Indiana Limestone Quarrymen’s Association

BEDFORD, INDIANA

1919

This book, being Volume I of the Indiana Limestone Library, is intended to have interest and to contain information in some degree for both architects and laymen. It does not, by any means, pretend to cover the subject of Indiana Limestone completely.

Meanwhile the Indiana Limestone Quarrymen’s Association will be glad to answer any specific questions or give any help in its power with regard to Indiana Limestone, its qualities, uses, etc. It will also be glad to furnish samples of the stone to illustrate any points which may be in question.

Ever since the days when it took one or two months in a sailing vessel to go to Europe, Americans, in constantly increasing numbers, have made the trip; made it mostly as a pilgrimage to the art and architecture of the Old World. They have worshiped at the shrines of sincere art and sincere craftsmanship.

Before the great Gothic cathedrals (largely built of limestone, by the way), they have stood in awe pointing out one to another the elaborate stone sculpture and tracery, the feathery spires and pinnacles; with knowing looks they have called the attention to the wonderful craftsmanship of the stone walls and buttresses, to the manner in which stones have been chosen, not for their absolute likeness in color, nor for their perfect similarity of texture, but for the infinitely delicate variety of both tone and texture which they show, thereby making even the plainest and most uneventful surfaces of walls interesting and attractive to the eye.

Having paid their esthetic respects, no doubt from the fullness of their hearts, to the works of the Old World masters; having had their holiday and turned “back to the plow,” as they say; they have (with a small but very rapidly growing class of exceptions) forgotten all the nobility and beauty which is possible to architecture and built their own buildings by radically different standards or by no apparent standards at all.

When they have used brick it has been because there happened to be a brickyard handy; when they have used stone it has been because there was a quarry nearer than the nearest lumber mill; when they have used terra cotta it has been because some clever salesman has talked them into a fleeting admiration for the Yankee ingenuity and American commercial sufficiency which has made a clever imitation of genuine stone out of burnt clay, shaped into a hollow shell and glazed like crockery.

At about the time of the Civil War a few of the excellences of Indiana Limestone as an architectural material came to the attention of a small public. From the time when the first carload was shipped to Chicago from Bedford, down to the present day, the use of Indiana Limestone in all the worthier sorts of buildings has increased by leaps and bounds until today a substantial proportion of all the monumental buildings of the country is built of it.

But one of the best qualities of the stone and the one which was largely instrumental in the calling attention to it, namely, its uniformity and easy working quality has, in a measure, proved to be to its detriment. Quantities of perfectly homogeneous fine grain stone being available, builders, in spite of the lessons of European architecture and despite the fact that several distinct kinds of Indiana Limestone are to be found in every quarry, have until late years made it a practice to insist upon absolute uniformity in tone, color and texture throughout a building. Although many wonderful buildings have been built in this way, the practice has tended to rob the stone of its distinction and increase the temptation to use factory-made substitutes in its place.

Happily this practice, except in cases where for special reasons uniformity is desired, is decidedly on the wane; and, through the new American demand for sincerity in artistic expression, which is only possible in a worthy and genuine material, Indiana Limestone, “The Aristocrat of Building Materials,” has come into its own.

Why we, living on an Earth which is nothing but one great solid rock covered with a thin skim of soil and water; why we, with the authority of the whole history of human civilization to lead us in the direction of stone for a building material, should permit ourselves, even temporarily, to be turned away from it or to express ourselves in it wrongly it is hard, to see. The only likely explanation seems to be the youth of the American nation and its youthful enthusiasm for commercial efficiency.

Many of us get even more enthusiastic over a clever imitation or a substitute that “will do” (if it is salable) than we do over the original, worthy, true and genuine thing on which the imitation is based. Of course this state of mind is wrong and with the zealous assistance of the sincere and able architects of the country it is rapidly giving way.

Limestone

Limestone, because of its especially pleasing qualities, has always easily held the leadership among building stones wherever it could be had at all. The Pyramids are built of it. All Continental countries are filled with beautiful and historic examples of its use. Most of the great Gothic cathedrals are wrought from it. \Westminster Abbey, St. Paul’s Cathedral, and many other ancient buildings in London are of Limestone—Oolitic Limestone. They stand among the greatest and most beautiful of man’s works of building art, venerable and venerated—and Limestone they are built of.

Indiana Limestone

Yet the celebrated Portland Limestone of England, which is undoubtedly the best European building stone, is but a poor second to that great deposit which occurs in Lawrence and Monroe counties, Indiana, known geologically as the Indiana Oolitic Limestone. Although a great proportion of all kinds of buildings of any importance in the United States is of this material, its importance is but half-realized and comparatively few people even know it by name.

Indiana Limestone is just the sum of all the qualities which an architect, an engineer and a prospective builder together could ask for in a building material. It is beautiful in color and in texture; it is extremely strong. It can be worked with great facility and perfection. Yet, even when finely carved, it is, from any practical standpoint, everlasting. It is abundant, and this with its workable quality makes it far from costly. Its fire resisting quality is high. It can be had in blocks of practically any size. Finally, it bears upon its face the stamp of the original, the true and genuine, product of the great unfaltering hand of Nature, which has placed it far above the power of man’s efforts to imitate. In beauty, and dignity, the first consideration in a building material, Indiana Limestone is beyond compare. First, it is to be had in various shades, all of which come out of nearly every quarry. Thus a choice of effects can be had.

Buff Indiana Limestone

A color which is widely used is the so-called “buff” Indiana Limestone. As in so many other cases, the common name describes “buff” Limestone but poorly. When it comes from the quarry it is what might perhaps be called a sort of buff, but on exposure to the air it quickly changes to a beautiful yellowish gray which never alters thereafter, except for the better, though exposed to all sorts of atmospheric conditions, for hundreds of years. Since, in our “young country,” Indiana Limestone has been used for building only about fifty years, this would seem at first sight a hard thing to prove. But it must be remembered that we are talking of civilization’s first building material, the “Rock of Ages,” part and parcel of Mother Earth. It is the naturally exposed ledges of Indiana Limestone, which have resisted the attacks of the elements for untold centuries, which prove the permanence of it in color as well as in form.

Gray Indiana Limestone

Buff Limestone comes from the upper part of the quarry. From the lower part comes the beautiful gray (sometimes called “blue” by the trade). When freshly quarried it is a rather dark bluish-gray, which changes on seasoning, that .is, exposure to light and air, to a silvery, hazy gray very pleasing to the eye. In the color, both of buff and of gray stone, there is an indescribable softness, a wonderful depth of tone which” belongs to Indiana Limestone alone.

Variegated Indiana Limestone

The rarer Limestone of mixed colors (the trade calls it “mixed stone”), occurs in the quarry only where the buff stone joins the gray. It is variegated in color, no two blocks being exactly alike, and so is capable of producing, when laid up in the wall of a building, an effect of infinite and beautiful variety, sometimes described as “vibrant.” Even the plainest unbroken wall may be rendered interesting by the effect of texture which the variegated stone gives. Properly handled by a skillful architect it can also be so used .as to convey the impression of dignified maturity in a new building.

Cram, Goodhue & Ferguson, architects, of New York, who are famous as creators of Gothic architecture, have so used Variegated Indiana Limestone in several famous churches with telling effect. Among these is the Fourth Presbyterian Church of Chicago. There are many buildings built in America of the uniform buff and gray limestones for which a European architect, his imagination influenced by daily contact with buildings of venerable age, would have chosen the variegated stone. Its use where special effects are desired, is rapidly increasing in this country among thoughtful architects, especially for churches and public buildings (except those of classic design), although its comparative scarcity must of course preclude the possibility of its use becoming general.

An especially graceful manner of using the variegated stone is in the construction of residences. Here the variation of color and marking, while taking nothing from the dignity of the building, lends a homelike and livable atmosphere to it, compared with the more formal suggestions of the stone of uniform color. Variegated stone- makes homes of houses.

Special Varieties

In addition to the three main varieties of Indiana Limestone just described there should be mentioned the following which are in demand for special purposes.

1. A stone of occasional occurrence and of a rich dark and distinctly bluish color. 2. An extremely hard and nearly pure white variety of very fine and somewhat crystalline structure. 3. An extremely hard variety of gray, very useful for base courses, steps and similar, purposes. 4. Indiana Travertine, a variety of Indiana Limestone of special decorative possibilities which closely resembles the; much used foreign Travertine.

Structure

The structure of Indiana Limestone is very interesting geologically. The formation is called Oolitic from the Greek: òoion, egg, and lithos, stone, because the many little bodies of which it is composed suggest the roc or eggs of fish. In the Lower Carboniferous age Indiana was the bed of an ocean which abounded in small shell-bearing animalculae, mostly bivalves and univalves, and of hundreds of different species. Dying as they did by hundreds of thousands of millions, their shells, mostly smaller than pinheads, and some of microscopic size, formed on the sea floor a great massive bed of carbonate of lime over 97% pure. To examine any piece of Indiana Limestone with a powerful glass is to lay before the eye a most entrancing exhibit of the minute sea life which existed no one knows how many hundreds of thousands of years ago. There are shells like those of tiny oysters, tiny clams; shells like tiny snails, tiny bits of lace, and tiny things you never saw before. Indiana Limestone consists wholly of these shells cemented together with a film of pure calcium carbonate. In certain corners and pockets of the Limestone quarries and at the thin edges of the stratum where evidently the sea water was shallow, large fossil shells are abundant, but the stone containing the large fossils is not ordinarily used as building material. It is because Indiana Limestone is composed of practically pure shell lime with only an infinitesimal proportion of silica, magnesia, and oxide of iron that it is so inert chemically as to resist perfectly the corrosive gases in our smoky city air.

Texture

The texture of Indiana Limestone varies from almost invisibly fine to rather granular. For interior work and sculpture the very finest, most homogeneous texture is frequently demanded, but discriminating architects are by no means so anxious to have it for exterior use as they once were. The present, and unquestionably the right practice, is to avoid the monotonous effect of perfectly uniform units, by using both finer and more pronounced grain in proper proportions to get what is known architecturally as “texture” in the wall itself, except when, for special reasons, uniformity is desired. Some architects prefer to use the fine grained stone for the lower courses of their buildings, and the more granular stone higher up.

Practical Qualities

If Nature had set about laying down the Indiana Limestone deposits with no other end in view than man’s convenience, she could have done nothing that she has not done in her magnificent incidental way. This stone, which once exposed to the air, as in a building, becomes practically everlasting, yet is not too hard when it first comes from the quarry to be cut with case into all manner of architectural and sculptural shapes, and is tough enough to be carved into the most delicate and permanent tracery and ornament. Two important results of this fact are beautiful artistic effects and comparatively low price. Most of the simpler architectural forms, such as blocks, sills, lintels, mouldings and columns, are turned out with the greatest ease by machinery with none of the great cost of hand tool work, but with all its dignity of result.

Large Scale Production

The production of Indiana Limestone is a great modern industry in the most modern sense of the term. If your conception of what it may be like is based on youthful memories of “the old stone quarry” where you probably used to hide or swim as a youngster, you would surely be astonished at the actual facts.

The Indiana Limestone industry is organized on what may be termed a factory basis. Two whole counties are liberally sprinkled with enormous quarries from which mountains of Indiana Limestone have been taken. Millions of dollars are invested in modern machinery, equipment and buildings and a network of railway spurs. Great and highly organized forces of men are employed. The result is that Indiana Limestone can be produced and delivered at comparatively low prices with all the facility and promptness of a manufactured article.

Stone Cut Up by Diamonds

Diamond saws are circular saws with teeth of diamonds set into them. These teeth are true diamonds as much as the costly jewels that grace dainty fingers. They are, however, not transparent, and consequently have no value as jewels, but being the hardest substance known, they can actually cut through hard stone at the rate of several inches per minute. The blocks and slabs as they come from the saws of course show slightly the marks of the saw teeth, and these are cither mechanically rubbed or planed smooth machine-tool finished or hand dressed.

An astounding process which furnishes an everyday sight at the stone cutting plants is the turning of stone columns on a lathe apparently with the greatest ease.

(See cut, page. 20.)

The long rough blocks are clamped and centered in a lathe, and, slowly revolving, are turned down with automatic precision by a chisel-like cutter to any required dimensions. This makes the hewing of stone columns a comparatively simple matter, and turned work, from small posts or balusters to massive columns a single one of which is a big carload, is handled with ease and practically perfect accuracy.

When one considers the sense of dignity and worth imparted to any building by even a porch of Indiana Limestone, the importance of this workable quality is easily seen.

Why Indiana Limestone is Easily Worked

It is not only its workable quality, however, which makes Indiana Limestone so kind to the stone cutter, to the architect or artist who designs the building or statue, and to the man who pays the bills. There are plenty of kinds of stone soft enough to cut readily, which are not workable, and plenty more not worth working. Indiana Limestone is a massive formation, homogeneous, tough and free from the cleavage planes or partings along which some stones split or scale on exposure to the weather. Many stones have a distinct layer formation, and consequently will split in one direction more readily than in another. Indiana Limestone, on the contrary, will split, chip or cut with almost equal facility up and down or crosswise.

Strength

An astonishing thing about this astonishing stone of history is that in spite of its easy-working quality it is extremely strong. Few building stones in commercial use compare with Indiana Limestone in this respect. The average crushing strength of Indiana Limestone in two-inch cubes is over 10,000 pounds per square inch. In units of the sizes ordinarily used for building it is even stronger. The weight borne by the piers which support the enormous

(Portland, Eng.)

limestone dome of St. Paul’s Cathedral in London is only about 278 pounds per square inch. Even the solid masonry shaft of the Washington Monument, 555 feet high, puts a pressure on its foundation of only about 313 pounds per square inch; and the stone piers of Brooklyn Bridge, supporting the vast weight of the causeway in addition to their own weight, exert a pressure of but 396 pounds per square inch on their bases. It is thus easily seen that Indiana Limestone can very much more than support any load likely to be put upon it.

Elasticity

Perhaps the quality of Indiana Limestone that the layman would be least likely to expect is its great elasticity. A bar of Indiana Limestone three or four feet long can be noticeably bent or deflected by the application of sufficient pressure, and, when released, will instantly spring back to its original straightness. When struck with a hammer it gives out a clear, metallic bell note almost like that of a bar of steel. This means that Indiana Limestone is the most elastic of all kindred substances. At first glance one is inclined to class this quality as “interesting but not important.” Yet as a matter of fact the power to submit to distortion without permanent deformation is among the most valuable qualities a building material may have.

Consider the strain put upon a block of stone that’s inside surface within a building may be 50 or 60 degrees hotter or colder than its outside surface exposed to the weather. One side of the block is contracted, and the other expanded, an enormous pressure being put upon it by the expansion of its fellows. Consider a change of temperature between midnight and noon of 50 to 70 or more degrees which often occurs in perpendicular walls exposed to direct sunlight. Only an elastic material can easily tolerate this sort of thing year after year. This is one of the great points (to say nothing of architectural beauty and dignity) at which Indiana Limestone shows its wonderful adaptability to building purposes and also one of the great points at which manufactured substitutes for it fail.

Blocks of Any Size to Be Had

The only limit to the size of the blocks of Indiana Limestone which may be had is what a derrick may lift and a freight car carry. The stone is ordinarily cut from the quarry into blocks much larger than it is possible to lift out and split up into less unwieldy sizes before lifting. Although this is no special advantage as regards the majority of building units it makes Indiana Limestone invaluable for certain purposes. Large statuary groups can be sculptured from single pieces of stone. Each of the Sphinxes in front of the building on the cover of this book was cut from a single block,

IG}^ x 7% x 8%

feet in size and weighing about 200,000 pounds as it came from the quarry. One-piece columns and pedestals of most massive and impressive dimensions can readily be had. The very essence of a beautiful column is in its imposing upward thrust, unbroken by joint, crevice or blemish. And what can convey a more affecting impression of dignity than a column mightily made by Nature through a billion infinitesimal deaths, mightily thought, mightily wrought, and mightily transported by the brain and hand of man, grown cunning through the passing of ten thousand generations?

Fire Resistance of Indiana Limestone

What else should a perfect building material have to its credit? Well, fire-resistance, for one thing. Here as everywhere, Indiana Limestone shines by its own light. Fire-resistance is a term that does not fully express all that the experienced mean by it. It should really be called “fire-and-water-resistance.” Indiana Limestone, under laboratory test, shows complete absence of ill effect when heated up to temperatures of about 1,000 degrees Fahrenheit and quenched with water. At the temperature of melting aluminum, about 1,157 degrees Fahrenheit, the stone shows a slight tendency to crumble at the edges when quenched with water. Samples heated to cherry red, about 1,500 degrees Fahrenheit, show considerable calcination and at temperatures considerably above this point calcination gradually becomes more and more complete until finally the stone is converted into quicklime. These experiments have been repeated on a sufficient number of specimens from various localities to make the test conclusive, and show beyond a doubt that Indiana Limestone, up to the point of calcination (turning into quick-lime) may be considered a fire-proof material. The point is that it also embraces just as high resistance to the application of water while the stone is hot. When tested, as the limestone above referred to was tested, most other kinds of stone, some of which have a higher resistance to fire alone than Indiana Limestone, crumble, burst, or go to pieces like glass. But let all the truth be told ALL decorative or architectural materials (as opposed to purely structural materials) are liable to be ruined or greatly damaged by exposure to extremely hot fires, dense smoke and douching with cold water. The walls may stand, and may often be serviceable as

icalls,

after the fire, but they will seldom be of much value as things of beauty if the fire has been anything like severe enough to test the quality of Indiana Limestone. Indiana Limestone will come through the ordeal of fire better than almost any other material for these reasons:

1st. Any fire hot enough over any considerable area to cause calcination of Indiana Limestone would mean “building and contents a total loss,” 710

mailer what it might be built of.

2nd. Indiana Limestone \msfire-and-icater-rcsislance to a degree which gives it a very high degree of damage-resistance and damage-resistance is really the thing desired.

3rd. Indiana Limestone, even when stained by smoke (or otherwise) can easily be restored to its original color by scouring or rubbing, while practically all other materials, may be injured beyond redemption by smoke alone.

We offer the proof of the above along with the assertions. We said we should ask you, after the truth about fire-resistance was all told, to look at the picture

on page 2C.

Now, having told the truth, we do hereby ask you to look at that picture, to read what is under it and to consider how well it bears out the facts we have stated.

Durability

One who, never having seen it before, should see Indiana Limestone as it comes from the quarry, however vividly he might be impressed by its rugged elegance, would not guess in a dozen guesses that the Great Sphinx, the Pyramids of Gizah, the main parts of the temples Abydos and the Sun Temple of Abusir, as well as a large proportion of the famous temples of Karnak, their ages measured not in hundreds but in thousands of years, are built of it, or, rather, of a limestone of similar shell formation, but geologically probably hundreds of thousands of years younger. Yet such is the case. And such being the case, we can only smile at the thought of looking for signs of deterioration in the “old” limestone buildings of the United States, some few of which have reached the lusty youth of fifty years.

To dispel any lingering vestige of doubt let us allude again to the limestone cathedrals of Europe and those of England, to St. Paul’s, and Westminster and others, those called by name having been built in past centuries of Portland Limestone, chemically inferior to, but pictrologically identical with Indiana Limestone. And let us allude again to the clear sharp arises of the anciently exposed ledges in the Bedford-Bloomington quarry district. Let us then speak no further about durability. It seems hardly needful to do so.

Ideal Shipping Location

Another point at which Nature was kind in regard to Indiana Limestone is in having located it at what is now almost the center of population of the United States. Bedford and Bloomington, Indiana, in Lawrence and Monroe counties respectively, are the centers of production and their central location coupled with excellent railroad facilities has made Indiana Limestone in actual practice “The Aristocrat of Building Materials” in every state in the Union and most of the provinces of Canada. The wonderful architectural qualities of Indiana Limestone, capped by the three things which tend toward reasonable price—shipping location, modern organization and abundant supply—all co-operate as though by a carefully arranged plan to concentrate in Indiana Limestone the very acme of merit as a material for the construction of all classes of buildings which are wholly or in part of decorative purpose, from the small residence or apartment, the dignified store or bank to the great edifices of commercial, religious, public or monumental purpose. And its use is not confined to the exterior of these buildings, but finds a thousand opportunities for interior beautification in the finer buildings of every class. Can anything more be asked of a single building material? Is not Indiana Limestone in truth the aristocrat of the building world?

Service Bureau

We maintain for the free use of architects, builders, and owners, prospective or actual, a Service Bureau. This Bureau is prepared to answer all questions about Indiana Limestone and its most economical and otherwise advantageous uses; to furnish finished samples; to assist in locating special stone for special uses and in general to render to those interested in Indiana Limestone any service within its power. It can supply photographs of Indiana Limestone buildings of all kinds, or details thereof, to illustrate what can be accomplished in the direction of your special interests or desires. It will be a pleasure to perform any of these services for you. The Bureau makes no charges, and places no conditions upon the service it renders or endeavors to render. Do not hesitate to ask us.

CHEMICAL ANALYSIS (AVERAGE) … Indiana Limestone

Carbonate of Lime… 97.20

Silica…1.09

Oxide of Iron ‘.49

Magnesia .37

Water and Loss .19

Average Weight .” 159 Ibs. per cu. ft.

Ratio of Absorption… .1 1 to 42

Average crushing strength 10,041 Ibs. per sq. in.

Background

Edwin F. Guth, Sr., was bom in St. Charles, Missouri in 1875. According to the 1906 and 1912 Book of St. Louisans, he began his business career in 1893 with the Interstate Electric Company. Nine years later, Guth and three associates (including his brother, Oscar) formed the St. Louis Brass Manufacturing Company in May of 1902; the company was incorporated in that year with a capital of $50,000. The company designed, engineered and manufactured electrical light innovations and lighting fixtures in addition to brass and bronze castings for hand rails, mantels, andirons and grates. At the time of incorporation, Edwin F. Guth, Sr., was treasurer, his brother Oscar was a salesman. Two associates, George S. Watts and Charles M. Wempner served as president and vice-president.4 Within eighteen months of incorporation, the firm’s assets were gone.

After 1903, Edwin, Sr, was president and Oscar was treasurer; Watts was listed as vice-president and Wempner as secretary.

Shortly before the 1904 Louisiana Purchase Exposition (1904 St. Louis World’s Fair), Watts and Wempner lost interest in the company and Edwin, Sr., bought them out with assistance from his father, Frederick. Guth soon won a contract for 20,000

feet of polished brass hand rails for the Fair. In addition, Guth’s specially designed electric lights with hand-wrought light fixtures lit the Tyrolean Alps exhibit building at the Fair. This particular project of the Swiss government was daring in construction and lighting treatment for the time.

Apparently, the job was so successfully executed that it resulted in Guth securing a similar lighting contract at the Fair for an exhibit for the Brazilian government.

Due to the demands of the Fair and prospects of future business, Guth’s company was running to full capacity and soon outgrew its original manufacturing facility at 1112-1120 Market Street (demolished). In the 1906 Book of St. Louisans, Guth was credited with building up the largest chandelier business west of Chicago.

Elaboration: The Guth firm In 1907, Edwin’s father, Frederick, commissioned St. Louis architect John L. Wees to design a three and five-story factory, warehouse and salesroom at 2611 Washington Avenue (later changed to 2615) for the St. Louis Brass Manufacturing Company’s second and final home. Three years later, Guth began a fifty-two year career in electrical light and lighting fixtures in St. Louis with the St. Louis Brass Manufacturing Company “the largest manufacturer of lighting fixtures in the U.S.A.” (see figure 2)

In 1910, Edwin F. Guth, Sr., invented the first of over one-hundred influential lighting products that would influence the lighting industry forever the “Brascolite.” (figure 2) The decorative, yet functional Brascolite, introduced commercially in 1912 and patented in 1913, sold in the millions for the next eleven years.

The invention was an early semi indirect light combined with a glass bottom bowl; the unit was delivered ready to be wired onto the lighting circuit. It was the first such self-contained packaged unit in the St. Louis Commerce. (St. Louis: My 1959) v 33, p 22.

“Guth Lighting: Enlightened Solutions for 100 Years.” (St Louis: JJI Lighting Group, 2002).

‘ “Brascolite” lighting fixture. Patent #1,076,418. Oct 21,1913. Annual Report of the Commissioner of Patents for 1913, p. 199. And U. S. Patent Office Gazette, v. 195, p. 685.

The Brascolite was so successful that it led to the formation of a subsidiary company, the Brascolite Company; the company was incorporated in 1914 with a capital of $2,000, Edwin F. Guth was listed as president. Also in 1914, Guth founded the Luminous Unit Company to handle electrical supplies; the company was incorporated in Missouri in 1914 with a capital of $2,000.’

Figure 2: From Gould’sSt. Louis Red-Blue Book (1921)

ST. LOUIS BRASS MFG. CO.

Phones OO41 111 1*1. Manufacturers

Kinloch, Central 1980 Vfin WjKhllWtfin iVP f ”

Bell, Bomont 3200 LUl\l II tlOMIHglUII HlC. “BRASCOUTE”

Largest Manufacturers of Lighting

Fixtures in the U. S. A.

We are also prepared for the following on a large scale: Deep Drawing and Stamping, Porcelain Enameling, Metal Spinning,

Polishing and Plating, Bronze Grills, Brass Rail and Machine Shop

Numerous lighting inventions continued up to 1912 when Guth and an internationally known local surgeon, Dr. Willard Bartlett, Sr., 10 invented the “Noshodolite” (also known as the Bartlett “Noshodolite”). This invention eliminated hand shadows during surgery by combining a series of eight reflectors giving 360 degrees of illumination. A 1921 Guth publication, Brascolite Bulletin for Hospitals, contained a list of 36 hospitals representing eighteen states and three countries that endorsed the Noshodolite’s medical superiority. Further, in 1929, the Noshodolite was advertised as “the most scientifically

designed fixture for the illumination of the surgical operative field that has ever been offered the medical profession.”

Both companies listed the same officers (per St Louis Brass Mfg. Co. incorporation) in the same positions except Charles M Wempner and George S. Watts were listed as VP and secretary respectively. “Missouri Historical Society Bulletin. July 1950, v. VI, TL 4, p. 556. Dr. Bartlett, Sr., (1868-1950) a founding member of the American College of Surgeons, past president of the Southern Surgical Association (1920) and vice-president of the American Medical Association (1922) was the first American to teach pathology at the University of Berlin. While in Benin, Dr. Bartlett, Sr., proved for the first time that cerebral hemorrhage was caused by the rupture of a blood vessel in the brain (ironically it killed him). ” Guth, Edwin F. Co. “The New Noshadolite.” Catalogue # 24. Missouri Historical Society collection.

In 1923, the St. Louis Brass Manufacturing Company (merging with the Brascolite Company) changed its name to the Edwin F. Guth Company to honor the original founder and brilliant inventor, (figure 3) In that year Guth invented his “Guthlite,” a thin

blown glass globe used with a perforated enamel reflector for both upward and downward light. The invention of the “Guthfan,” followed in 1928. This patented Guthfan Conditionaire was considered the first real improvement in fan design and

principle since 1898 and the only fen that scientifically provided complete cooling, refreshing air circulation and good lighting in one complete unit. 12 The fan’s ability to draw cool air from the floor and circulate it throughout the room without disturbing hot upper air was then an entirely new principle. 13 Guth’s fan earned the first patent on a fan in thirty years and was a prototype of today’s ceiling fans. Hotels, architects, businesses, restaurants and hospitals from New York to Kansas City endorsed the superiority of the Guthfan well into the mid-1930s.

Figure 3: From Gould’s St. Louis Directory (1927)

Brascolite Aglite Gulhlite

DESIGNERS – MANUFACT U RE R S

lighting Equipment

ST LOUIS. U.S.A.

PHONE JEFFERSON WASHINGTON

3200 AT JEFFERSON

A joint venture of the General Electric Company and the individual utility companies during the early 1930s, known as the “Better Light Better Sight” campaign, kept the Edwin F. Guth company busy during the Depression. Of the eight companies listed as lighting equipment manufacturers in the 1930 Gould’s St. Louis city directory, three companies were Guth-owned and operated; only the Edwin F. Guth Company was listed as a lighting fixture manufacturer. During this period, Guth announced his latest ” Guth, Edwin F. Co. Catalogue # 6,1935. Missouri Historical Society Business Catalogue Collectioa

^ St. Louis Commerce. (St. Louis: July 1959) v 33, p 22.

The Edwin F. Guth Company was the only company listed in the 1929 Gould’s Classified Business Directory of the City of St. Louis under lighting equipment. In 1931, three of seven lighting equipment manufacturers were Guth-related. In 1932, one of two was Gum-related and out of eleven lighting invention, the “Super Illuminator” which provided indirect light with a luminous exterior glow. Shortly thereafter in 1937 came his “Optilux,” another indirect lighting fixture.

The “Optilux” had an enclosed top of prismatic glass effective in reducing brightness in normal viewing angles in schoolrooms. One year later in 1938, he invented the “Diagonal Spectral Assimilation” fixture, a lamp that combined the efficiency of a mercury-vapor lamp with an incandescent lamp for both direct and indirect lighting units.

The first fluorescent lamp was introduced at the 1939 New York World’s Fair; an instant success, it ensured the coming of the fluorescent light era of the 1940s. Guth’s version (his 1940 “Jacknife Guthlite”) included a light fixture hinged downward so it could be serviced from the floor. During World War n he invented “The Cadet.” Six thousand and six hundred of these four-foot long units, each limited by the government to three pounds of steel, were installed in the U. S. Military Academy at West Point.

Guth continued to develop incandescent and fluorescent lighting fixtures through the 1970s, expanding the company into the institutional and industrial lighting markets. In 1950, Guth revolutionized the food industry with “Plascolume.” For the first time, a one-piece PVC gasket was integrated into the stainless steel lens frame to achieve the ultimate seal of FDA approval. Still in 1952, Edwin F. Guth, Sr., announced his “Gratelite Louver Diffuser,” a 3/8-inch cube plastic molding that shielded lamps and hid them from all normal angles. By 1959 his “Prismoid Louver” appeared on the scene to permit a two-fold prism control of light. This complicated louver was made of plastic with tiny apertures on one side flaring out to larger openings on the other; with the apex up, a concentrated distribution of light was achieved and turned over, a wide beam of light resulted.

While many companies were leaving downtown St. Louis for St. Louis County during the 1960’s, Guth chose to remain in the city, and expand his business there. On its sixty-year anniversary (January 22, 1962) the Edwin F. Guth Company broke ground on a new 100,000 square foot addition (addition to building C). Designed by St. Louis architects, William B. Ittner, Inc., and Wedemeyer and Hecker, the column-less “60th Anniversary equipment dealers, two were Gulh-related In 1933, one of three lighting equipment manufacturers was Guth-related; two of eight lighting equipment dealers were Guth-related. In 1935 and 1936, three of six lighting equipment manufacturers were Guth-related.

15 St. Louis Commerce. (St Louis: July 1959) v 33, p 22.

16 “Guth Lighting: Enlightened Solutions for 100 Years.” (St Louis: JJI Lighting Group, 2002).

Building” cost $800,000. In a press release on the ground breaking ceremonies, Mr. Guth

Stated “The new Guth plant addition is built with faith in the continued growth of

the city of St. Louis… at a time when St. Louis has lost many businesses it is

important to reaffirm our belief that downtown St. Louis has tremendous

business potential.” 17

This addition housed new production machinery and finishing equipment; smaller

adjoining buildings housed paint mixing facilities, baking ovens, and storage. With the

new addition, The Edwin F. Guth Company had a total of 350,000 square feet of

productive manufacturing area. The addition was recently separated from the Guth

complex by the installation of a permanent interior wall approximately thirty feet inside

the addition, (see site map, page 18)

Edwin F. Guth, Sr., died on January 31, 1962 with 160 U. S. Patents in the lighting

industry field to his name; most of which were issued during the period of significance. 18

In addition to his accomplishments as an inventor, Guth was included in the Gould’s Blue

Book, a social registry of the city’s most prominent citizens, as early as 1905. He held a

number of important local company directorships including: Celotex Corp., National

Gypsum Co. and the Jefferson Bank. Guth was also a member of the Shrine and he held

active memberships in the Liederkranz Club, Missouri Athletic Club, Latin American

Club, Algonquin Country Club, Rotary and the St. Louis Metal Trades Association. He

was awarded the “Modern Pioneer” award by the National Association of Manufacturers

around 1959 which honored him for being “a Modern Pioneer on the frontier of

American Industry.” The award was given in recognition of “distinguished achievement

in the field of science and invention which has advanced the American standard of

living.” 19

After his death, Guth’s son Edwin F., Jr., took over as president. Remaining true to his

father’s desire to stay in the city of St. Louis, in 1963 Jr., commissioned a second

production building. This 8,000 square foot building (building E) at the west, was built

to house a new Hi-Production Hydroform machine (a product of the Cincinnati Milling

” Edwin F. Guth Company. Press Release, January 22,1962. Missouri Historical Society Collection.

18 Donald Hencke. Edwin F. Guth Company, News release. January 31,1962. Also confirmed in Salute to

St. Louis Industry, 1963. Landmarks Collection.

” Sr. Louis Commerce. (St Louis: July 1959) v 33, p 22.

Machine Company). Frank Currans, one of the six original engineers who developed the

machine, was in charge of the Guth Company’s Hydroform operations. This machine

enabled Guth Lighting to fabricate extremely intricate reflector designs that had not yet

been considered cost-effective. The machine was so versatile that Ford sent Guth molds

and had the company form some of the tail light assemblies used on the 1965 Ford

Mustang.20

Guth lighting illuminates the Missouri State Capitol, the Soldier’s Memorial, Kiel

Auditorium, the St. Louis Police Headquarters, the Scottish Rite Cathedral, the Civil

Courts Building, and the Municipal Opera. Nationally, the Government Printing Office

at Washington was relit three times with Guth lights (before 1959). Nearly 20,000 Guth

fixtures were installed in Chicago’s U. S. Post Office. Numerous other projects (before

1959) included the Presidential News Conference Room in Gettysburg, twenty-eight

Steam Plants of TVA, the Philadelphia National Bank, the First National Bank of Mobile,

the Glenn L. Martin Company drafting room, and the Cooper-Bessemer Corporation

drafting and design room in Mount Vernon, Ohio.

The Edwin F. Guth Company’s immeasurable contribution to the American lighting

fixture industry extended over sixty years; from 1907 onward, products were invented,

designed and manufactured by his firms at 2615 Washington Avenue. The company

remained under Guth ownership until it was sold to JJI Lighting Group in 1966 (after the

period of significance); Guth Lighting remains in business at this same address today,

bears the Guth name and continues to manufacture and distribute Guth products world

wide. Today, Guth’s parent company, JJI Lighting Group, is the largest privately-held

lighting manufacturer in the country and the ninth largest worldwide.21

0 “Guth Lighting: Enlightened Solutions for 100 Years.” (St Louis: JJI Lighting Group, 2002).

1 Sorldns Directory of Business & Government. St Louis Region Edition, 2003. v 2, p 817.

Bibliography

A Preservation Plan for St. Louis. Heritage and Urban Design Division. (St. Louis, 1995)

Book of St. Louisans: A Biographical Dictionary of Leading Men of the City of St. Louis.

(St. Louis: St. Louis Republic, 1906 and 1912)

City of St. Louis building permit records. St. Louis City Hall, Office of the Assessor.

City of St. Louis deed abstracts. St. Louis City Hall, Office of the Assessor.

Edwin F. Guth Company catalogues and bulletin, (catalogues #6; #10, 1923; Brascolite

Bulletin for Hospitals, 1921; #24, 1929; #40, 1942. (St. Louis: E. F. Guth Co.).

Guth Celebrates 100 Years of Lighting Innovation. (St. Louis: JJI Lighting Group, 2002)

and featured in Lighting Design + Application. (May 2002).

“Guth Lighting: Enlightened Solutions for 100 Years.” (St. Louis: JJI Lighting Group,

2002).

“Guth Lighting Moves Forward with St. Louis.” St. Louis Globe-Democrat, Sunday

Magazine. (Feb 3, 1963).

Jensen, DanaD., ed.. Bulletin of ‘the Missouri Historical Society. (St. Louis: MHS, July

1950) v. VI, n. 4, p. 556.

Maril, Nadja. American Lighting: 1840-1940. (Atglen: Schiffer Publishing, 1995).

Missouri Historical Society Archives: Coiporations and Industry Collection. “Salute to

St. Louis Industry,” 1963; “Welcome to Guth Lighting,” 1962; “Guth Builds New

Hydroform Plant,” 1963; “Release on Ground-Breaking Ceremonies,” 1962; “Founder of

the Edwin F. Guth Company Dies,” 1962

St. Louis Chamber of Commerce News. (St. Louis: Chamber of Commerce) December

18, 1929. v. 1-3, Novl2, 1928-Dec 31, 1929. St. Louis Public Library Collection.